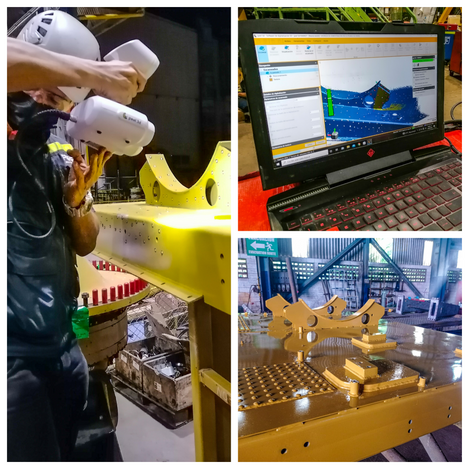

3D scanning captures complex geometries in seconds. This activity can replace long hours of traditional metrology. The result will always be obtaining an accurate and detailed model in the shortest possible time

The great advantage over traditional methods will always be that we can complete projects in a few days that could take weeks or even several months

4.0 Industry

3D modeling technologies play a fundamental role in the Fourth Industrial Revolution, also known as Industry 4.0. This revolution is characterized by the convergence of digital, physical, and biological technologies, transforming how industries and businesses operate. In this context, 3D modeling holds several key significances

Design and Prototyping: 3D

3D modeling technologies enable designers and engineers to create accurate and detailed virtual models of products and components. These models can be used for virtual prototyping, which speeds up the design process and reduces the need for expensive physical prototypes.

Innovation and Customization

3D modeling facilitates experimentation with designs and the exploration of new ideas. This encourages innovation by allowing quick creation of product variants and customization to meet specific customer needs.

Process Optimization

Through 3D simulation, companies can analyze and optimize manufacturing, logistics, and operational processes. This helps identify inefficiencies, reduce costs, and improve quality.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a key technology in Industry 4.0. 3D modeling is essential for creating the design files required to print three-dimensional objects layer by layer.

Collaboration and Communication

3D modeling enables more effective communication in the supply chain and among multidisciplinary teams. Virtual models can be shared and reviewed in real-time, enhancing collaboration and decision-making.

Predictive Maintenance

In Industry 4.0, assets and machines are connected through the Internet of Things (IoT). 3D modeling can be used to create digital models of these assets, facilitating predictive monitoring and maintenance

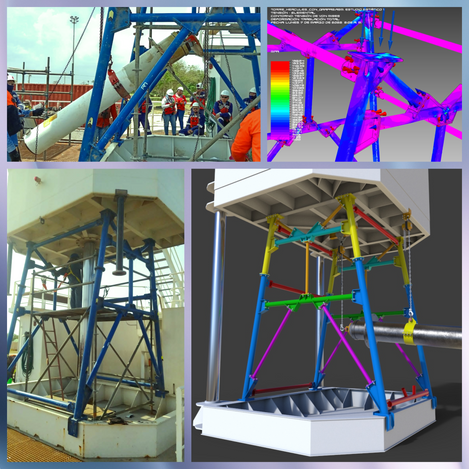

The industry we serve

Our services are useful in all types of industries where engineering blends with design and the need for precision. Parametric´s market objective focuses on large companies as well as medium and small businesses that provide services and are part of the production chain, such as metalworking workshops and independent consultants

Machinery for mining and construction industry

port and shipping industry

Cement and aggregates industry